Checkout

Shopping Cart

0 Item - £0.00

Part-on Tools Blog

22 July 2025

For anyone working with threaded inserts, the FAR KJ45/S hydropneumatics tool is a reliable partner. To ensure flawless operation and prevent issues like insufficient setting or mandrel breakage, understanding and correctly performing stroke adjustment is paramount. This guide will walk you through the essential steps, ensuring your tool operates at peak efficiency.

Why Stroke Adjustment Matters

The stroke of your FAR KJ45/S needs to be precisely adjusted based on several factors: the dimensions of the insert, its type, and the thickness of the material you are clamping. Incorrect adjustment can lead to significant problems, including:

- insufficient setting of inserts: This can compromise the integrity of your work, causing the insert to rotate within its housing.

- Possible breakage of the mandrel: Excessive deformation due to an incorrectly set stroke can damage both the insert and the tie rod, potentially leading to costly repairs and downtime.

Key Steps for Stroke Adjustment

Before you begin, always ensure the tool iswith compressed air. This is a crucial safety measure to prevent accidental operation during the adjustment process.

- Prepare for Adjustment:

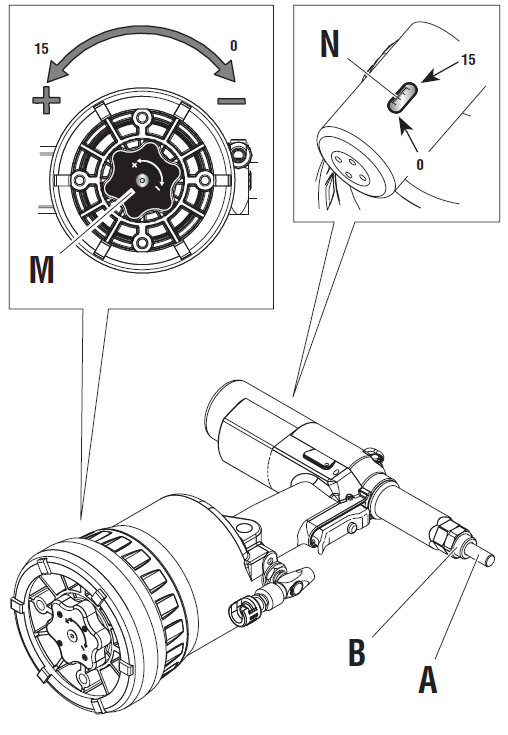

- First, confirm that the threaded mandrel(A) and head (B) assembled on your KJ45/S are appropriate for the size of the insert you intend to set. If not, change the size accordingly.

- Crucial Safety Step: Discharge any remaining air from the tool and stop the air feeding by moving down the slider of the air-entry valve (Q). All adjustment operations must be performed when the tool is not fed.

- Adjusting the Stroke with Knob (M):

- Locate the stroke-adjusting knob (M).

- Rotate the knob (M) to adjust the stroke:

- Turn the knob in the direction indicated by the (+) symbol to increase the stroke. Increasing the stroke will decrease the "h" distance, thereby increasing the clamping action.

- Turn the knob in the direction indicated by the (-) symbol to decrease the stroke.

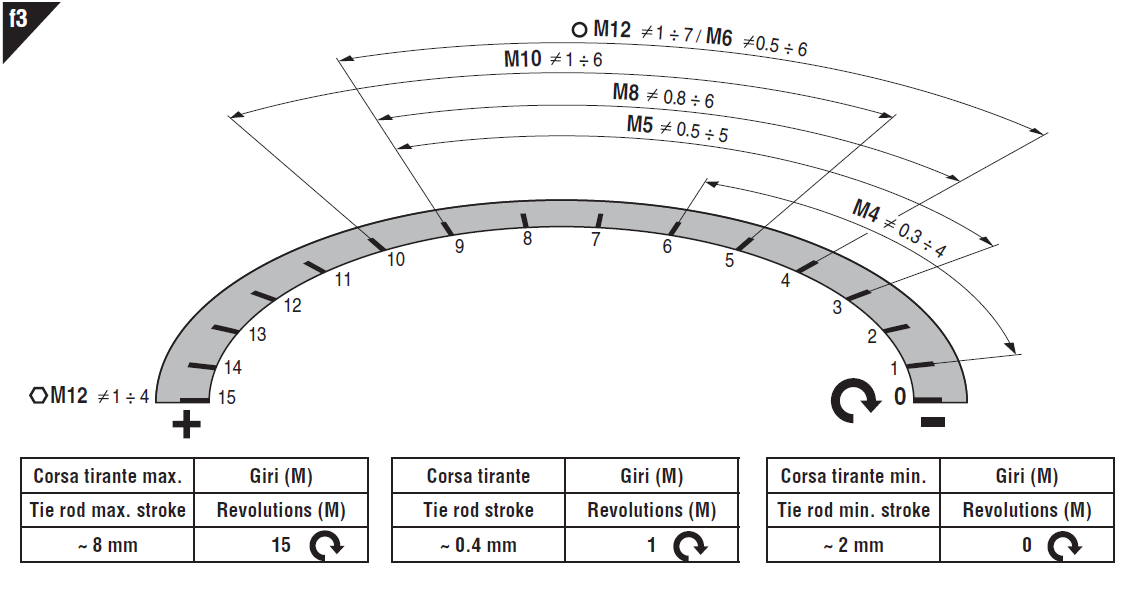

- You can also refer to the Revolutions (M) table to understand the mandrel stroke based on the knob's revolutions. For instance, 15 revolutions equate to approximately 0.4 mm of tie rod stroke, while 0 revolutions correspond to a minimum stroke of approximately -2 mm.

- Verifying the Adjusted Stroke:

- Once you've made your adjustment, you need to feed the tool by moving up the slider of the air-entry valve (Q) to visually check the changed stroke.

- Compare the reading on the stroke indicator (N) with the values provided in the manual's table (fig. f3) to ensure correct adjustment.

BLACK FRIDAY WEEK IS ALMOST HERE! Unlock Premium Tool Deals

(Nov 24 – Dec 1) Utilise Our Promo Codes For Special Discounts!

Read More

FAR Rivet Nut Tool Comparison: KJ45/S vs. KJ46 vs. KJ47 Setting Methods

Manual, Hybrid, or Automatic? Matching Your Production Line to the Right FAR Rivet Nut Tool

Read More

Part-On Gears Up for Growth

Q3/Q4 Initiatives Drive Quality, Innovation, and Team Expansion

Read More

Pneumatic vs. Cordless Battery Riveters for Modern Manufacturing

Which option is best suited for your application and production requirements?

Read More

Repair, Don't Replace

Your Impact Starts Here: Choose Repair, Don't Replace. What Kind of World Do You Want?

Read More

The Balancing Act Of Business Ownership and Motherhood.

Meet Marie, our managing director. A mother, a business owner... a superhero!

Read More

Black Friday November 2023 | Deals You Dont Want To Miss!

Mega Deals Available For Applicable Orders Received By 30th November 2023!

Read More

What are the advantages of using aluminum profiles in construction or manufacturing?

The Advantages of Using Aluminium Profiles in Construction and Manufacturing

Read More

What is a rivet and how do they work?

Exploring the Versatility of Blind Rivets: How They Work and Why They're Essential.

Read More

Learn The Difference | Rivets, Rivet Nuts & Rivet Stud's |

What Is The Difference Between, Rivets, Rivet Nuts and Rivet Stud's? | Learn Today | Industrial Fastening Knowledge

Read More

Part-On in support of Birmingham Hospice

Part-On will be donating 1% of net profits for all website orders received starting from Jan 2023!

Read More

Halloween 2022 - 7 DAYS OF OFFERS

Spooky deals this Halloween season, Don't miss out of Part-On's 7 days of offers!

Read More