Checkout

Shopping Cart

0 Item - £0.00

Part-on Tools Blog

27 September 2023

Exploring the Versatility of Blind Rivets: How They Work and Why They're Essential

When it comes to fastening materials together, blind rivets have become a go-to solution for various industries and DIY enthusiasts alike. These versatile fasteners offer a reliable and efficient way to join materials without requiring access to both sides of the workpiece. In this blog, we will delve into the world of blind rivets, exploring how they work and why they have become an essential tool in countless applications.

1. Understanding Blind Rivets:

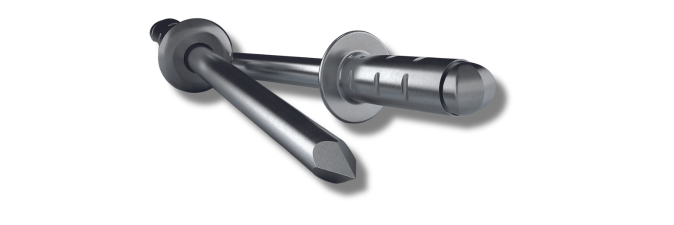

Blind rivets (also known as pop rivets) are mechanical fasteners designed to permanently join two or more materials. Unlike traditional rivets, blind rivets can be installed from one side of the workpiece, making them perfect for applications where access is restricted or limited. They consist of a cylindrical body with a mandrel, which is a thin rod that extends through the center of the rivet.

2. The Riveting Process:

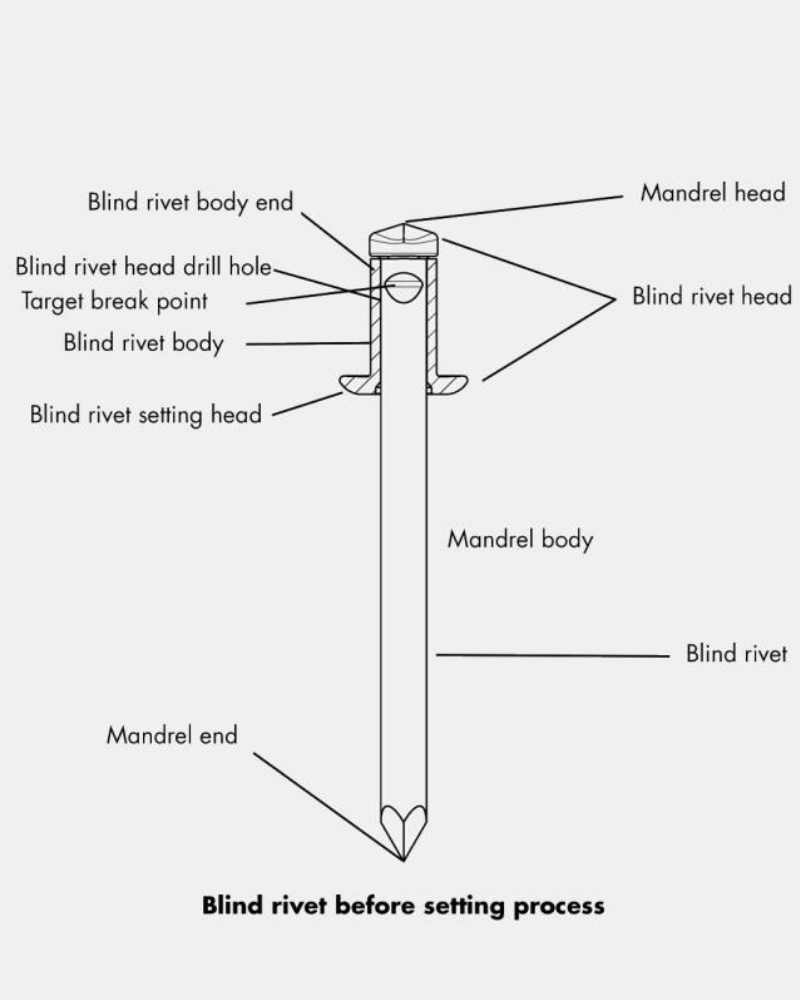

Installing blind rivets involves a straightforward process that can be accomplished with basic tools. Here's a step-by-step breakdown of how blind rivets work:

a. Preparing the Workpiece:

First, the materials to be joined are aligned and pre-drilled with a hole that matches the diameter of the blind rivet.

b. Inserting the Rivet:

The blind rivet is inserted into the pre-drilled hole, with the mandrel extending through the workpiece.

c. Applying Pressure:

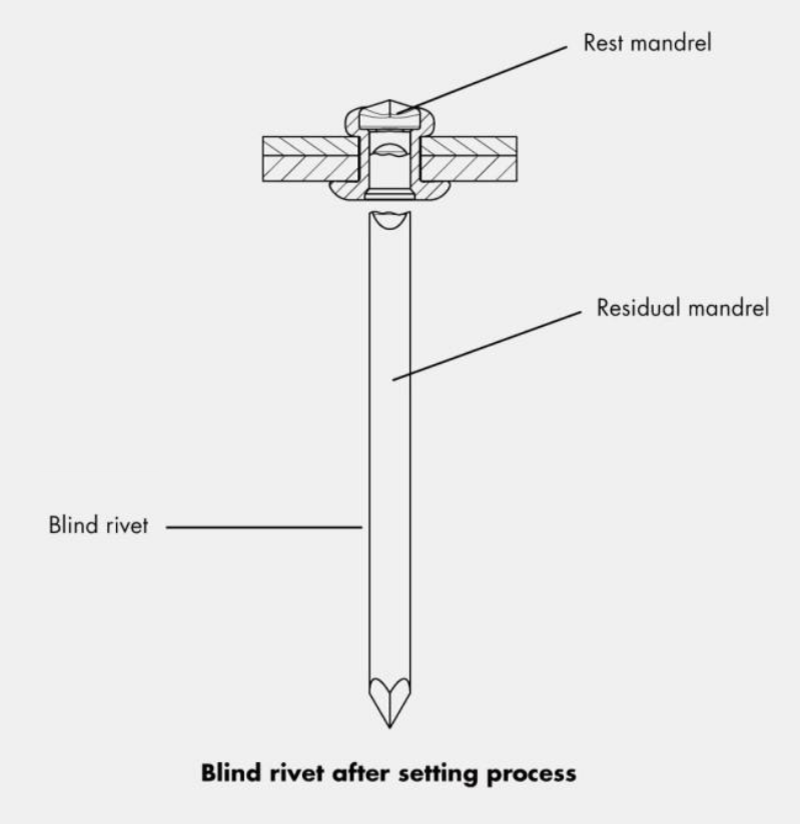

When using a rivet tool, pressure is applied to the blind rivet's head. This causes the body of the rivet to expand, creating a secure grip on the materials being joined.

d. Breaking the Mandrel:

While applying pressure, the mandrel is pulled back into the rivet tool, causing it to break off near the head of the rivet. This ensures a tight and secure connection.

3. Advantages of Blind Rivets:

Blind rivets offer several advantages that make them a popular choice in various industries:

a. Accessibility:

Installing blind rivets from one side of the workpiece makes them ideal for applications where access is limited or restricted.

b. Speed and Efficiency:

Blind rivets can be installed quickly and easily, reducing assembly time and increasing productivity.

c. Versatility:

Blind rivets can join different materials, including metal, plastic, and even wood, making them suitable for a wide range of applications.

d. Cost-Effective:

Blind rivets are cost-effective compared to other fastening methods, providing a reliable and durable connection at an affordable price.

e. Vibration Resistance:

Blind rivets form a secure and resilient joint, with the expanded blind end increasing resistance to vibrations and ensuring long-term durability.

4. Applications of Blind Rivets:

Blind rivets find applications in various industries, including automotive, aerospace, construction, and manufacturing. They are commonly used in assembling furniture, automotive body panels, HVAC systems, and electrical enclosures, among many other applications.

Blind rivets have revolutionized how materials are joined, offering a reliable, efficient, cost-effective solution for countless applications. Blind rivets, the unsung heroes of fastening technology, have revolutionized the way materials are joined together in situations where traditional methods fall short. With their ability to create sturdy connections from a single side, blind rivets have become indispensable in modern construction, manufacturing, and repair industries. Whether you're a professional or a DIY enthusiast, blind rivets are a go-to choice for achieving secure and durable connections in your projects. Understanding their mechanics and appreciating their many benefits allows us to leverage their invisible strength and ensure the integrity of countless structures and products worldwide. So, the next time you encounter a seemingly seamless assembly, remember that behind the scenes, blind rivets are working their magic.

BLACK FRIDAY WEEK IS ALMOST HERE! Unlock Premium Tool Deals

(Nov 24 – Dec 1) Utilise Our Promo Codes For Special Discounts!

Read More

FAR Rivet Nut Tool Comparison: KJ45/S vs. KJ46 vs. KJ47 Setting Methods

Manual, Hybrid, or Automatic? Matching Your Production Line to the Right FAR Rivet Nut Tool

Read More

Part-On Gears Up for Growth

Q3/Q4 Initiatives Drive Quality, Innovation, and Team Expansion

Read More

Pneumatic vs. Cordless Battery Riveters for Modern Manufacturing

Which option is best suited for your application and production requirements?

Read More

Repair, Don't Replace

Your Impact Starts Here: Choose Repair, Don't Replace. What Kind of World Do You Want?

Read More

The Balancing Act Of Business Ownership and Motherhood.

Meet Marie, our managing director. A mother, a business owner... a superhero!

Read More

Black Friday November 2023 | Deals You Dont Want To Miss!

Mega Deals Available For Applicable Orders Received By 30th November 2023!

Read More

What are the advantages of using aluminum profiles in construction or manufacturing?

The Advantages of Using Aluminium Profiles in Construction and Manufacturing

Read More

Learn The Difference | Rivets, Rivet Nuts & Rivet Stud's |

What Is The Difference Between, Rivets, Rivet Nuts and Rivet Stud's? | Learn Today | Industrial Fastening Knowledge

Read More

Part-On in support of Birmingham Hospice

Part-On will be donating 1% of net profits for all website orders received starting from Jan 2023!

Read More

Halloween 2022 - 7 DAYS OF OFFERS

Spooky deals this Halloween season, Don't miss out of Part-On's 7 days of offers!

Read More

Post Comments